Creating a PID controller program in Structured Text (ST), a high-level programming language used in PLC (Programmable Logic Controller) programming, involves defining the logic to compute the PID control's output based on the process error, integral, and derivative calculations. Below is an example of how such a program might be written in ST. This example assumes you have a basic understanding of PLC programming and the context in which this PID controller will operate.

```structuredtext

PROGRAM PID_Controller

VAR

Kp: REAL := 1.0; (* Proportional gain *)

Ki: REAL := 0.1; (* Integral gain *)

Kd: REAL := 0.01; (* Derivative gain *)

Setpoint: REAL := 100.0; (* Desired process value *)

MeasuredValue: REAL; (* Current process value *)

DeltaTime: REAL := 0.1; (* Time between calculations, in seconds *)

Error: REAL;

PreviousError: REAL := 0.0;

Integral: REAL := 0.0;

Derivative: REAL;

Output: REAL;

END_VAR

Error := Setpoint - MeasuredValue; (* Calculate current error *)

Integral := Integral + (Error * DeltaTime); (* Update integral *)

Derivative := (Error - PreviousError) / DeltaTime; (* Calculate derivative *)

Output := (Kp * Error) + (Ki * Integral) + (Kd * Derivative); (* Compute output *)

(* Update for next calculation *)

PreviousError := Error;

(* Your code to apply 'Output' to control the process goes here *)

```

### Key Components:

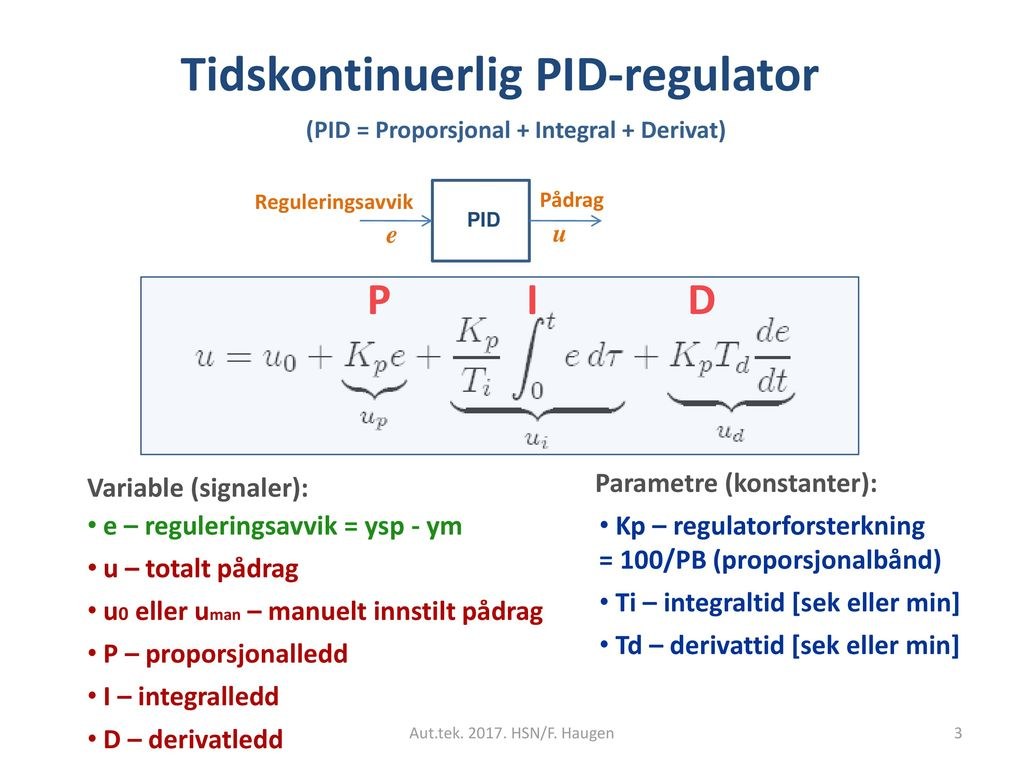

- **Kp, Ki, Kd:** These are the PID controller's tuning parameters. You'll need to adjust these based on your specific process to achieve stable and responsive control.

- **Setpoint:** The target value for the process variable you're trying to control (e.g., temperature, pressure, level).

- **MeasuredValue:** The current value of the process variable. This would typically be read from a sensor.

- **DeltaTime:** The time interval in seconds between successive PID calculations. This should match the cycle time of your control loop.

- **Error, PreviousError, Integral, Derivative, Output:** Variables used to compute the PID controller's output. `Error` is the current difference between the setpoint and the measured value, `Integral` accumulates the error over time, `Derivative` represents the rate of change of the error, and `Output` is the value applied to the process to drive the measured value towards the setpoint.

This ST code snippet is a basic implementation. Depending on your application, you might need additional logic to handle scenarios like integral windup or to scale the output to the specific requirements of your control element (e.g., a valve or a motor speed controller).

SystemerTjenester

SystemerTjenester ForumOm oss

ForumOm oss Norsk

Norsk

Norsk

Norsk